ILMSENS MEASURES THE DIFFERENCE

Layer Thickness Radar

Ground Penetrating Radar for Road Construction

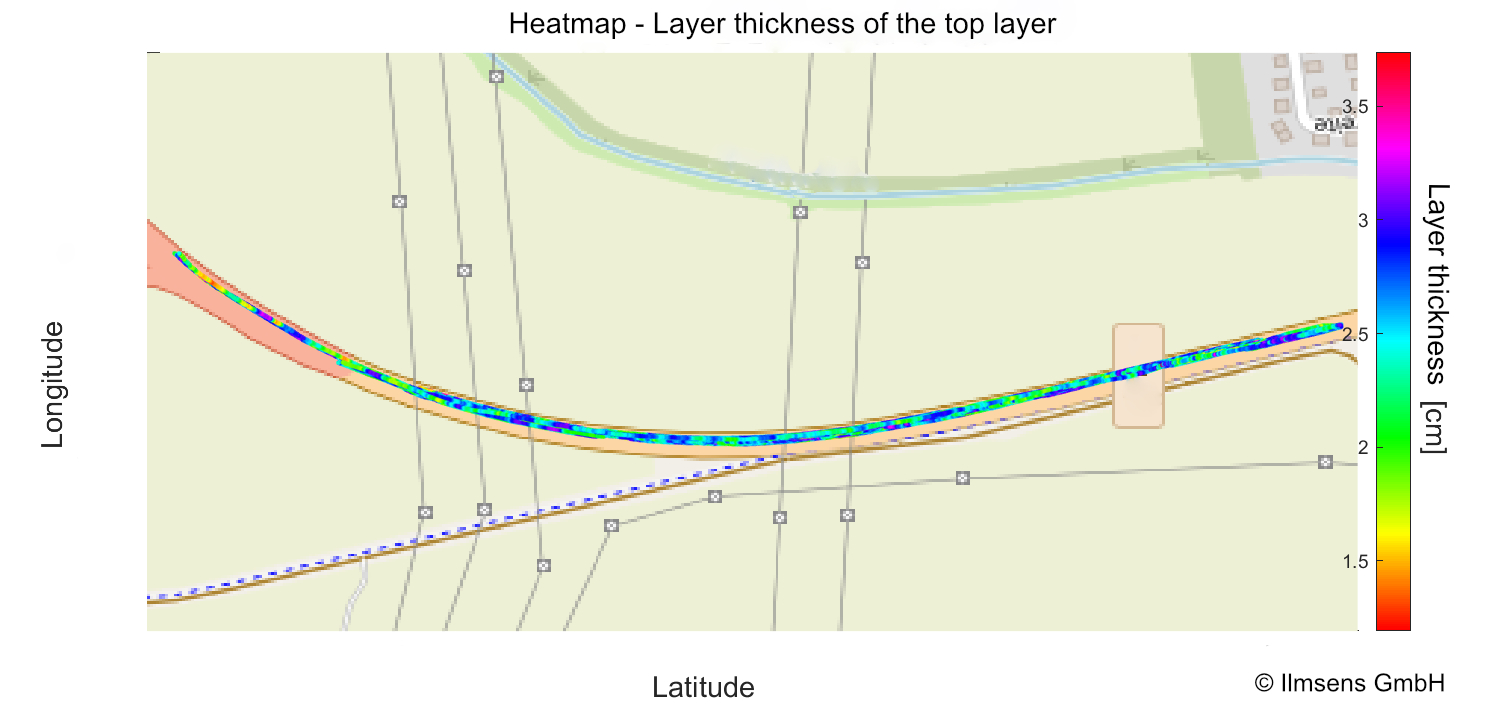

With the Ilmsens ultra-wideband layer thickness radar we can measure the layer thickness of asphalt in real time – before and during the paving process or afterwards for controlling purposes. It can be utilized to monitor the thickness of the layer during paving for adjusting of the material quantity and for documentation or to review the layer thickness after pavement. In comparison to state of the art techniques like drill core extractions, the Ilmsens Layer Thickness Radar is non destructive and can give continuous information of the subsurface - not only samples. That is why ground penetrating radars in general are a perfect fit for such measurement tasks.

Continuous measurement!

High precision of ± 1 mm!

Real-time capable!

Easy to retrofit!

Non-destructive measurement!

Tailor the system to your requirements!

APPLICATIONS

ADDED VALUE

Why using Ilmsens Layer Thickness Radar?

- Robust and compact design

- Seamless integration into the existing process

- No contact to asphalt necessary

- Adaptable to all interfaces

- Admissible system

- Harmless for humans and machines

"Precise real-time measurement of the layer thickness of asphalt in the paving process makes it possible to ensure that the required standards are met while reducing the amount of material."

FAQ - Frequently Asked Questions: Layer Thickness Radar

| What is the layer thickness radar? | + | |

|

With the Ilmsens ultra-wideband layer thickness radar, the layer thickness of asphalt can be measured before,during or after the paving process. The hardware

can be easily retrofitted on various construction machines. The software will enable real-time data evaluation of the ultra-wideband radar data to determine the layer thickness of

asphalt. In the presented prototype, the software enables the measurement procedure and the data is evaluated afterwards. It can be adapted for other materials using calibration

measurements.

|

||

| How does the layer thickness radar work? | + | |

|

To provide the layer thickness, the distance between the surface and the layer changes needs to be measured by the radar. The main challenge is to find the

reflection of the layer change between two asphalt layers in the radar data, as the reflection of the layer change is quite weak due to the low contrast between the two asphalt

materials. But those minor reflections can be detected and the topography of the layer change can be followed. The layer thickness is just the difference between the distance of

two consecutive layers to the radar or the surface and the first layer.

The layer thickness radar thus also delivers information about the topography of the layers in the subsurface. |

||

| What are the advantages of layer thickness radar over other measurement methods? | + | |

|

In comparison to state of the art techniques like drill core extractions, ground penetrating radars are non destructive and can give continuous information

of the subsurface - not only samples. That is why ground penetrating radars in general are a perfect fit for such measurement tasks.

Ground penetrating radars are typically designed with a narrow bandwidth transmission signal for examining the ground at great depth with lower range accuracy by increasing depth. The low bandwidth often leads to poor distance resolution, so that two close objects cannot be distinguished from each other. By increasing the bandwidth of the transmitted signal the range resolution can be increased. By using a stable clock, the distance accuracy can be improved. The Ilmsens’ ultra-wideband radar combines a transmission signal with an ultra-wide bandwidth with a stable clock and thus gives a high distance accuracy and resolution also in areas close to the surface. Due to the regulations, the transmission power is limited and hence the penetration depth is low. Thus, the ultra-wideband ground penetrating radar is a perfect fit for measuring the layer thickness of asphalt (or other materials) in real time with an accuracy of ± 1 mm. The layer thickness can be measured or stored during asphalt paving, during maintenance or asphalt removal. The next release will cover real-time evaluation and thus the layer thickness can be displayed via an interface, too. |

||

| How accurate are the results of the layer thickness radar? | + | |

|

The utilisation of an ultra-wideband radar enables a good range resolution and accuracy, so that layers close to the surface can be detected and the layer

thickness can be determined with an accuracy of ± 1 mm.

|

||

| What are typical applications of the layer thickness radar? | + | |

|

The layer thickness radar can be used to measure the layer thickness of different layers of a road. It can be utilized to monitor the thickness of the layer

during the paving for adjusting of the material quantity and for documentation or to review the layer thickness after pavement.

|

||

| What needs to be considered when the layer thickness radar is retrofitted to construction machinery? | + | |

|

The size of the sensor system, the required mounting locations and ambient conditions are listed in the data sheet. It is mandatory that the individual

components are mounted in the required location. The location is:

|

||

| What interfaces does the layer thickness radar offer? | + | |

|

The interfaces of the layer thickness radar can be adjusted to your specific needs. At the moment, the only interface is the power supply, which is +24 V

(min. +20V, max. +28.5 V) and max. 4 A.

|

||

| What does the transferred data look like? | + | |

|

The data can be processed according to your needs. You can choose between

|

||

Get more Information